WINDOWS

We do all phases of windows from basement sliders to bay windows.

MINIMUM ORDER: Our minimum order for basic double-hung or slider windows is 3 windows, due to economy of scale reasons. We’ll do three, but our pricing per window is lower if you order five or more windows. Don’t leave out that lousy garage window, because it will be cost-prohibitive to ever change it as a stand-alone project.

STORM WINDOWS ARE OBSOLETE. They are as obsolete as single-pane wood windows. I’ve been in business since 2008, and I have never installed a storm window. We only remove them. Hundreds and hundreds.

ALL VINYL WINDOWS are double-pane (or triple-pane), and they all tilt in and have insulating fuzz around the edges. Even the cheapest mechanical vinyl window that is worth less than $100. Don’t let a salesperson or mailed out flyer convince you this is a selling point for their product over others. There are other window features, specifically the balance mechanism, the fusion-welding, the design-pressure rating, and the U-factor that are best used to evaluate actual quality of one brand versus another.

NEW WOOD WINDOWS: We sell and install all brands of wood windows, including Andersen, Pella, and Marvin

ENLARGE OPENINGS: We can enlarge or reduce openings for larger or smaller windows. This is often done with kitchens, especially where the bottom of old windows is in conflict with the modern standard countertop height. We can install headers and reframe openings.

CONFIDENT HOME REMODELERS

Serving Northern New Jersey and the Lehigh Valley

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButtonSlide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Windows are definately not a do-it-yourself project. Homeowners can easily make mistakes as follows:

Mistake #1:

We think it should be against building codes to install a Replacement Window without an exterior stop. NEVER let someone rip out your exterior stop moldings to put in a Replacement Window from the outside, and rely solely on aluminum coil and caulk to keep out the water. It's best to keep the exterior stop in place, and install from the inside by removing and reattaching inside trim.

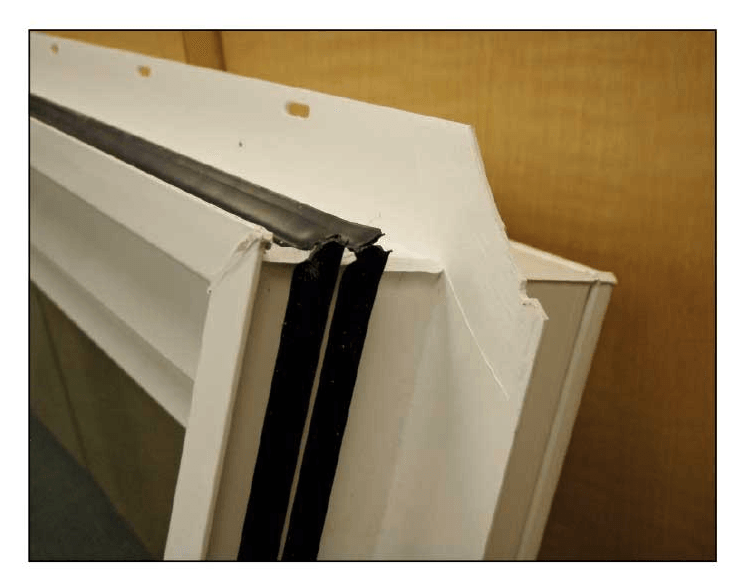

"New construction windows" have an exterior mounting flange that keeps out the water, and these windows always go in before the siding work. See the flange here:

And then the siding goes over the mounting flanges. It's fairly water tight. It's not as water-tight as the old way (exterior stops), but it's good. Replacement windows don't have that mounting flange, and instead they are designed to be snug to an exterior stop. See below,a Replacement Window.

That mounting flange is the difference between "new construction" and "replacement" windows.

There's absolutely nothing wrong with this window, UNLESS it is installed without that wooden exterior stop

Every house built before the days of New Construction Windows have exterior stops. They are vitally important to keeping out the water. (If you have storm windows, they are always mounted on the exterior stops). Exterior stops appear to have a square profile, but actually extend deeper. Aluminum coil is way too thin to effectively replace an exterior stop. Exterior stops and aluminum coil are both caulked when a new window goes in, but the 3/4" thickness of the wood is a far more effective water barrier than a thin and flimsy piece of aluminum. Got it?

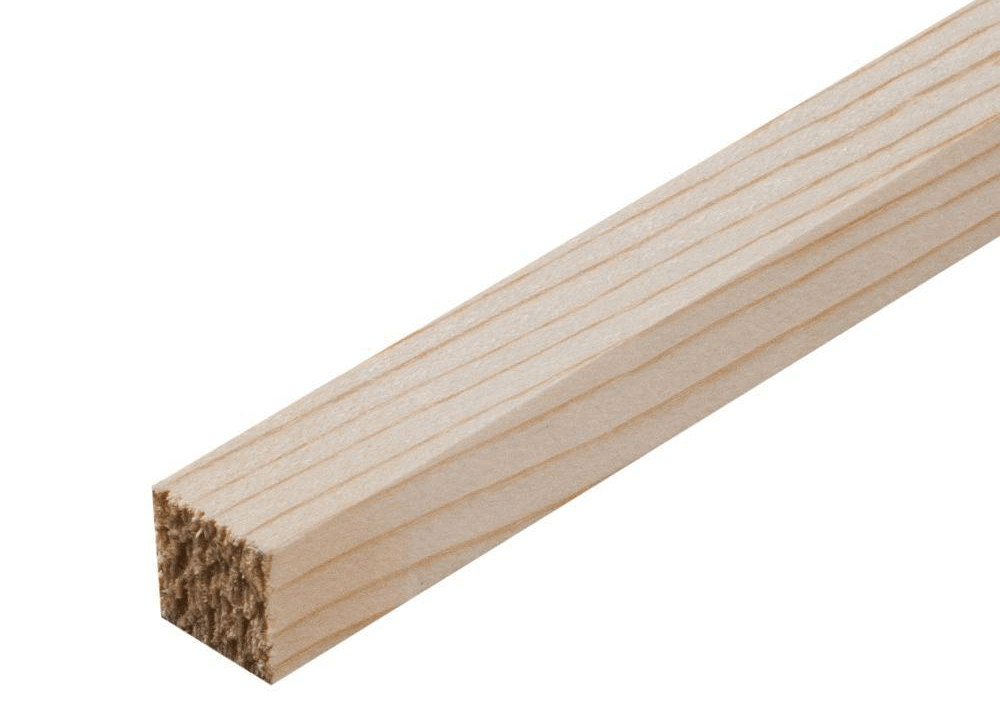

If you want new aluminum coil over the existing exterior stops, that's perfectly fine, it just cannot replace the exterior stops. See below, a new exterior stop:

Many or most window companies install replacement windows from the outside. Goodbye exterior stops. Sure the new aluminum coil looks great, but eventually IT WILL allow the water in, and cause damage. We see this problem all the time. That's why it should be against building codes.

As far as we are concerned, if a window has to be replaced from the outside, you will need new 3/4" x 3/4" exterior stops around the side and top, and then caulk it. And we never install from the outside, unless there's kitchen or bathroom tiles or stonework on the inside that prevent an interior installation.outside.

It's always best to install your new Replacement Windows from the inside, and keep those exterior stops. They may or may not need touch-up paint after the storm window is removed. We can always touch them up for a nominal cost, if needed.

Note: New Construction Windows have been on the market long enough that some customers are replacing them, which means the new window is a Replacement Window, not a New Construction Window. That is effectively the same as removing the 3/4" thick exterior stops, and relying on thin aluminum coil.

Mistake #2: improper shimming and leveling. If done improperly, the sashes will be drafty and wobbly, or won't close properly.

A window has to be leveled in 3 dimensions (left-right, top-bottom, and it must not be tilting in or out). A large window often needs an additional screw in the middle of each side (despite what the manufacturer says), and it must be shimmed prior to screwing.

Mistake #3:

Improper insulating. An air-tight window will leak heat if not insulated right. Needs expanding foam spray or stuff roll insulation

Mistake #4:

Missing or failed caulking causing drafts, water infiltration, and the infiltration of flies, insects and spiders and all sorts of creepy crawly things. Water infiltration will rot your sills and eventually the framing of the house or cause water damage on your walls. Make sure to use interior caulks and silicones that are paintable (kit/bath silicone is not). And must use a Silicone or equivalent on the exterior.

Mistake #1:

mis-measure the windows. If you are off by 1/4" either way, it could be a big problem

We can enlarge or reduce openings for larger or smaller windows. We can install Andersen, Marvin, & Pella wood windows, including casements, picture windows, and double-hung.

Customers (and even most contractors) can't distinguish between all the caulks, silicones, and adhesives out there. There is ONE brand that is far superior to all the others for exterior applications, and it is not GE. This is a trade secret not to be revealed online. Also, Alex and Alex-Plus painter's caulk cannot be used for the exterior, even though it says so on the tube.

QUALITY VINYL WINDOWS

I provide windows from several window manufacturers, depending on the quality of windows desired by the customer. I provide both wood and vinyl windows. I can sell and install any Andersen window except their exclusive Renewal By Andersen series. (Nobody else can get them) Don’t be in awe of the Andersen name, most of their sales are the 400 series that came out in 1980, with a 0.32 u-factor that was incredible in 1980, but now it’s low-quality. Technology has moved on, and other windows spec out much better.

The soft warm white of the interior wood still makes the 400 series attractive for aesthetic reasons. For some customers this is everything. Others couldn’t care less, and they want a window that is up-to-date and energy efficient. We can get windows with exterior grids that “look historic”, or have grids between the glass for easy cleaning.

I have sold hundreds of Alside windows, but have recently shifted to

Okna Windows

because they upgraded to a block-and-tackle balance system, like Renewal By Andersen.

This link illustrates the various window balance mechanisms: window balance mechanisms

Lots of people worry that “a vinyl window isn’t strong like wood”, and the vinyl might crack. It never does. The best OKNA 800 vinyl windows spec out with an AAM Design-Pressure Rating of 60, which qualifies for Miami/Dade County with their hurricane risk. And there’s no wood to ever rot.

Vinyl windows range from pure junk that may last 5 years to a lifetime window that will outlast wood. Double-pane vinyl window fail for same typical reasons, none of which are the vinyl:

1. The glass was broken by some force

2. Mechanical problems, especially with the balance mechanism, or casement hardware

3. Seal failure, causing mist between the glass panes

4. They were installed in a sagging porch, or a sagging wall

As a contractor, I have access to every brand of window out there. We directly install every window we sell, that way I can control the quality of installation. This is what we do. Even the best brands out there will have mechanical and leak-related problems if not properly installed.

BUDGET VINYL WINDOWS WITHOUT ENERGY-EFFICIENCY

The budget-level window that I sell is called the Anderson Silverline 1200. Anderson is known for wood windows, but around 2005 they purchased the Silverline vinyl window company to capture part of the vinyl windows market. It's a budget-priced window, but has fusion-welded sashes and frames. This means it is a strong window. Usually budget windows are selected by landlords who want the cheapest window possible, and they don't care how much the tenant is paying to heat the house (until the landlord has to replace the over-worked boiler). Other budget brands out there are "mechanical", which means screwed together. They might only last 5 or 10 years, and then they get foggy between the panes, they won't stay up, the hardware breaks, and other issues. We know this because we've replaced hundreds of really junky vinyl windows made by Air-Chek Window Depot (out of business in July 2012), Jersey Windows, and others.

The Silverline 1200 is the same price or within about $10 of the garbage brands, and it will easily last 25 or 30 years because of the fusion-welded frames AND sashes. I refuse to sell or install a junk window. Typically the urban landlord or real estate "flip" investor will remove 100 year old wood windows and 30-year old storm windows, and put in vinyl windows with zero energy efficiency that lasts less than 10 years. If you are going to put in a vinyl window, be smart. They look the same, but they are NOT all the same. Not even close. Spend the extra $10 for the Silverline 1200.

It's best to choose a window manufacturers that has been around for decades. They aren't going to disappear tomorrow, so the warranty means something. From the customer standpoint of achieving peace of mind, you can't do better. These manufacturers do not advertising or marketing of their own, they don't install windows themselves, and they sell only to Contractors. It's more cost-effective for them to have a qualified and experienced Contractor who provides the customers than to hire, train, and pay salespersons, and then advertise for leads. Most consumers still won't be familiar with these company names.

NEW CONSTRUCTION WINDOWS

New Construction windows are not, I repeat NOT, better than Replacement windows. This is NOT a newer and better technology. They are NOT more weatherproof. Builders these days want the cheapest of the cheap, with no attention to quality.

Now that building codes require R13 insulation between the exterior wall framing, so builders just throw a tyvek-material onto the exterior sheathing and slap on the vinyl siding without any insulation board. The R13 insulation is 3 or 4 times more insulation than the insulation board behind vinyl siding. The better-quality insulation sold now is the only thing better about "new construction".

The new construction window has a flange, and it is nailed into the exterior plywood. Water can still get behind the flange if it is not sealed right because siding is never 100% watertight over time. Home buyers, building inspectors, and architects don't realize that all these new construction houses that have these "new construction" windows; most of them will be leaking by the time they are 30 years old. I'm already seeing it on a few jobsites in Jersey City, circa 1990 construction.

The older-style replacement window, on the other hand, relies on exterior wooden stops (tall rectangular pieces 3/4" x 3/4" to keep out the water. 100-year old houses with exterior stops are still watertight around the windows, and that is before the days of high-quality caulking.

REMEMBER

New Construction windows cannot be used for "replacement" situations, and Replacement windows are rarely used for new construction because they are more labor-intensive to install.

TILTING PORCHES

If your porch is tilting or sagging, there are typically three problems with the side windows. First, there are long triangular gaps at the top of your windows, and then the sashes won’t open and close, or the panes will actually crack from the pressure. We walk away from these install requests. We will NOT install new windows for you. You don’t have a window problem. The porch needs to be fixed, and invariably that means jacking it up and digging new concrete footings. And then you can think about new windows.

NEVER INSTALL FROM THE OUTSIDE

On only the rarest occasion will we ever install from the outside. Other companies always install from the outside. Very foolish. What they don’t tell the customer is that this involves REMOVING the vitally important wooden exterior stop that holds the window in place from the outside. And then they bend a twist a flimsy piece of aluminum coil and put some caulk in its place. Completely inadequate. That window now has dramatically less structural integrity without the exterior stop holding it in place. And it will eventually leak. This install method should be against building codes (but it’s not). I remember one leaker in Jersey City around 2009, and how furious he was about the shoddy work another guy did. We don’t install a replacement window without an exterior stop, never.

If you want us to remove it so that the windows can be installed from the outside, there will be a separate additional charge to create and install a new exterior stop. We can rip a standard 1 x 4, and make stops. And we rarely ever do this. Most often it’s a bathroom or kitchen window with tiles on the inside. Sometimes its when there is sheetrock used as window jambs, and that’s usually shoddy work in around a basement slider.

INSIDE INSTALL

Windows typically come three basic ways

1. window is flush to the sheetrock edge, and there are casings. Usually newer houses. We remove the case molding and restore it when done

2. window is recessed about 1" - 1.25" and there is a little trim molding between the window and the case molding. For these windows, we just remove that small trim molding, and restore it when done.

3. It is a 1920's house with 5" - 6" wide chestnut trim width an additional backbend piece. These are prone to splintering due to age and their dryness, whether they are painted or not. They are typically installed with giant-size nails that complicate their removal. On some houses, the molding issue is so substantial that we'll install from the outside, and add new stop molding.

WHEN STORM WINDOW IS REMOVED

The typical window install involves removing a storm window that was screwed into the vitally important exterior stop that we just talked about. This leaves the exterior stop exposed, like it was when the house was built. Usually it is painted white, and the paint is in reasonable condition. Sometimes its not and needs painting. We can’t predict, and painting them is not included in our scope of work. When this problem is found, we’ll typically touch them up with white primer for very small fee.

ALUMINUM COIL

We don’t encourage it. It oxidizes and dents, and over time it makes the house look old and worn. If we can’t keep the coil there now, we encourage PVC boards like Azek and comparable brands. Plygem makes a better product than Azek, in our opinion. If you really want aluminum coil, we can do it for an additional cost.

QUALITY CAULKING

Alex and Alex-Plus caulk is a painter’s caulk that is great for the inside because it’s not gooey, and it goes on smooth. (The gooey caulk is lousy on the inside, it’s almost never sharp and clean). I don’t care what it says on the tube, a Painter’s caulk is never to be used outside, it will crack or separate in the winter. A caulk WITH THAT GOOEY QUALITY is what is needed on the outside. The gooeyness means it won’t crack or separate. We have a brand that we prefer, that is marketed as a caulk, but it is actually an adhesive. We use the long thin grey “caulk-saver” rods if the gaps necessitate it. Andersen sells these, and acts like they are the only source. LOL.

BASEMENT SLIDERS WITH DRYER VENTS ARE DISCONTINUED

Between 2017 and 2020, it appears that all window manufacturers discontinued making basement sliding windows with the built-in dryer vent. This was reportedly forced upon them by their insurance carriers. There’s been fires in dryer vents, and then the homeowners have sued everyone, including the contractor, the window vendor, and the window manufacturer. If the dryer was vented through the concrete wall, there still would have been a fire, but the non-combustible nature of the cement around the opening would have delayed and limited the spread of the fire. That’s their logic. You’ll have to bore a hole in the concrete wall. Good luck with that, the older concrete is, the harder it gets. The Hoover Dam will be drying and hardening for 500 years.

HOW TO TRIM RECESSED WINDOWS

We will never install sheetrock and a corner bead up to a window recessed into an opening. One reason is that the window can’t be replaced from the inside without ripping out the sheetrock…..ugggh. This is usually a basement remodel issue, but we’ve encountered it in condominiums, esp. 1980’s construction. We strongly suggest primed pine between the window and the sheetrock edge, whether it’s a 1 x 4, 1 x 6, or even a 1 x 10. And then you will have a nice wood extention jamb reaching from the window to the wall sheetrock, and you can put case molding around it. The pine extension jambs can always be removed and reinstalled to change the window.

It’s slightly cheaper on material to use sheetrock and a corner bead, but the labor to install a corner bead and spackle and sand winds up costing the contractor more. Sheetrock is bad for install cost reasons, it doesn’t look as nice, and it means the next window has to be replaced from the outside. So don’t do it.

For a small extra fee, sometimes I’ll suggest a little rounded protruding sill for houseplants or other items, and then there’s case moldings on the top and sides only

We bring pride and passion to every project that we undertake, with a professional team of designers, project managers and tradespeople.